Okay, Lars, this rather lengthy post is for you. I've sent you a number of parts for the gear tooth cutter in the mail, but these first steps you can do before the package arrives if you have time. My prototype was constructed primarily out of wood. You may decide it would be better to use steel or have other ideas for improvements, but I'll assume for the sake of expediency that you'll build it just like mine.

Precision during construction significantly affects the machine's ability to cut precise gear teeth. You should make sure your table is level before starting so that you can level various components throughout the assembly.

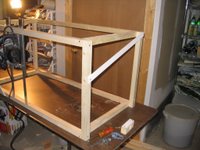

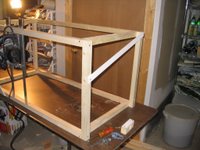

First, build the frame out of two-by-two lumber. The frame should be assembled exactly as in the photo (except for the diagonals which were not correct when this photo was taken) with 48" and 21" horizontals, and 27" verticals. I used 24" verticals, but you should build yours taller in order to accommodate our increased gear thickness.

First, build the frame out of two-by-two lumber. The frame should be assembled exactly as in the photo (except for the diagonals which were not correct when this photo was taken) with 48" and 21" horizontals, and 27" verticals. I used 24" verticals, but you should build yours taller in order to accommodate our increased gear thickness.

Diagonals should be added to keep the structure rigid, but the position of the side diagonals must be correct. They can terminate at the front no more than eight inches from the top of the frame. The side diagonals should be attached to the verticals so that there is a gap between the diagonals and the side horizontals.

Diagonals should be added to keep the structure rigid, but the position of the side diagonals must be correct. They can terminate at the front no more than eight inches from the top of the frame. The side diagonals should be attached to the verticals so that there is a gap between the diagonals and the side horizontals.

Next, build the spindle bar rails. The spindles will be mounted in top and bottom spindle bars (two-by-twos) that will run lengthwise through the frame. The spindle bar rails will guide the spindle bars, allowing them to move freely lengthwise. The spindle bar rails will also be adjustable front-to-back, allowing various gear blanks to be positioned nearer or further from the cutting blade.

The left spindle bar rail is made from two 27" two-by-twos separated by short two-by-two spacers at the top and bottom. Unlike mine, your spacers should be no more than two inches long.

The left spindle bar rail is made from two 27" two-by-twos separated by short two-by-two spacers at the top and bottom. Unlike mine, your spacers should be no more than two inches long.

Place the rail along the left side of the frame so that it is held against the frame by the left diagonal.

Place the rail along the left side of the frame so that it is held against the frame by the left diagonal.

Then carefully attach a short two-by-four (mine was 9.5" long, but I recommend about 14") such that the rail is held perfectly upright as it is adjusted from front to back. There should be a small gap between the rail and the table so that the weight is held by the two-by-four. Drill a pilot hole near the bottom of the rail, but do not drill it through the frame horizontal. This is for a set screw (see two photos up) that will be used to hold the rail in various positions.

Then carefully attach a short two-by-four (mine was 9.5" long, but I recommend about 14") such that the rail is held perfectly upright as it is adjusted from front to back. There should be a small gap between the rail and the table so that the weight is held by the two-by-four. Drill a pilot hole near the bottom of the rail, but do not drill it through the frame horizontal. This is for a set screw (see two photos up) that will be used to hold the rail in various positions.

Make the right spindle bar rail the same way as the left one, except that the two-by-four must extend 8.5" from the front edge of the rail. You might want to make your two-by-four few inches longer than mine toward the rear for improved vertical stability of the rail.

Make the right spindle bar rail the same way as the left one, except that the two-by-four must extend 8.5" from the front edge of the rail. You might want to make your two-by-four few inches longer than mine toward the rear for improved vertical stability of the rail.

The reason the right spindle bar rail has a longer two-by-four is to support the guide rack table. This is a 21.5" long, 7.5" wide board supported by two-by-fours at both sides. Use a short length of two-by-two as a foot at the rear of the left two-by-four. Note that you cannot add a foot at the front because the table must be able to extend over the front frame horizontal when the spindle bar rails are positioned forward for cutting smaller gears.

The reason the right spindle bar rail has a longer two-by-four is to support the guide rack table. This is a 21.5" long, 7.5" wide board supported by two-by-fours at both sides. Use a short length of two-by-two as a foot at the rear of the left two-by-four. Note that you cannot add a foot at the front because the table must be able to extend over the front frame horizontal when the spindle bar rails are positioned forward for cutting smaller gears.

The left two-by-four needs to extend far enough to the rear so that the bottom spindle bar can ride on top of it. Hopefully you won't have to, but I had to chisel the top of mine down a bit due to a bowed bottom spindle bar. With the spindle bar (or any two-by-two since you haven't made the real spindle bar yet) in place, add little front and rear guide blocks to the top of the two-by-four. These will keep the guide rack rigid with respect to the spindle bar path. The rear guide block needs to be pretty short.

The left two-by-four needs to extend far enough to the rear so that the bottom spindle bar can ride on top of it. Hopefully you won't have to, but I had to chisel the top of mine down a bit due to a bowed bottom spindle bar. With the spindle bar (or any two-by-two since you haven't made the real spindle bar yet) in place, add little front and rear guide blocks to the top of the two-by-four. These will keep the guide rack rigid with respect to the spindle bar path. The rear guide block needs to be pretty short.

Attach a 12" two-by-two to the top of the guide rack table along the front so that the edge facing the spindle bar is parallel to the spindle bar and exactly 22.8 cm from the center of the spindle bar.

Make the bottom spindle bar from a single 61" two-by-two. Drill 1/4" holes into the top of the bar about 1" deep (not all the way through) for the blank spindle and guide spindle. The holes should be made along the center line of the bar and should be perfectly vertical. The blank spindle hole should be 26" from the left end of the bar, and the guide spindle hole should be 13" to the right of the blank spindle hole.

Make the bottom spindle bar from a single 61" two-by-two. Drill 1/4" holes into the top of the bar about 1" deep (not all the way through) for the blank spindle and guide spindle. The holes should be made along the center line of the bar and should be perfectly vertical. The blank spindle hole should be 26" from the left end of the bar, and the guide spindle hole should be 13" to the right of the blank spindle hole.

Add the tension bar perpendicular to the bottom spindle bar. It should be 18" long, attached about 1/2" to the right of the center point between the two spindles.

Add the tension bar perpendicular to the bottom spindle bar. It should be 18" long, attached about 1/2" to the right of the center point between the two spindles.

The tension bar needs a little cut-out at the spindle bar end in order to move freely above the little guide block on the rack table support. You should also add a foot to the tension bar, precisely sized to level the spindles. The foot can be no more than 3.5" away from the spindle bar or else it will run into the rear frame horizontal when the spindle bar rails are positioned toward the rear for cutting larger gears.

The tension bar needs a little cut-out at the spindle bar end in order to move freely above the little guide block on the rack table support. You should also add a foot to the tension bar, precisely sized to level the spindles. The foot can be no more than 3.5" away from the spindle bar or else it will run into the rear frame horizontal when the spindle bar rails are positioned toward the rear for cutting larger gears.

Make a little tension slider that slides freely along the tension bar. Drill a 1/4" hole about 1" deep into the slider for the tension spindle.

Make a little tension slider that slides freely along the tension bar. Drill a 1/4" hole about 1" deep into the slider for the tension spindle.

Mount the slider on the tension bar and add rubber bands that pull the slider toward the end of the bar.

Mount the slider on the tension bar and add rubber bands that pull the slider toward the end of the bar.

The top spindle bar is identical to the bottom spindle bar except that the spindle holes go all the way through, and there isn't any of that tension bar nonsense. You'll need to sand down the ends of both spindle bars in order to allow smooth motion through the spindle bar rails.