In March of 2005, Emily and I visited Belfair, Lars's house in Fairbanks. Alas, we saw no

northern lights, but we did get to view the

wonders of the

World Ice Art Championships. While we were there, Lars and I got to talking about how fabulous some of the kinetic sculptures were. These included ice slides that you could slide down and little, basket-like, one-person merry-go-rounds. We also saw a couple of ice chains that led Lars to marvel, "You could build a working clock out of ice!"

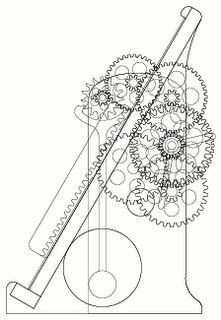

I couldn't banish the idea from my head. On the flight home, I abandoned the concept of powering an ice clock with weights on chains in favor of the "falling hammer" mechanism, which I later abandoned in favor of the "sliding sled." Several months and many discarded ideas later, I had a complete design for the clock and a rough design for a gear tooth cutter.

I had hoped to send Lars a working model in the mail, knowing that he would instantly understand my proposal to enter this year's event. As the new year loomed, however, I still hadn't constructed a gear tooth cutter, so I decided to try to convince him without the model. It wasn't hard.